JB Design has begun to incorporate the use of Finite Element Analysis (FEA) software in projects where our services include product design assistance, rational analysis, glass design, among others.

So what exactly is Finite Element Analysis (FEA)

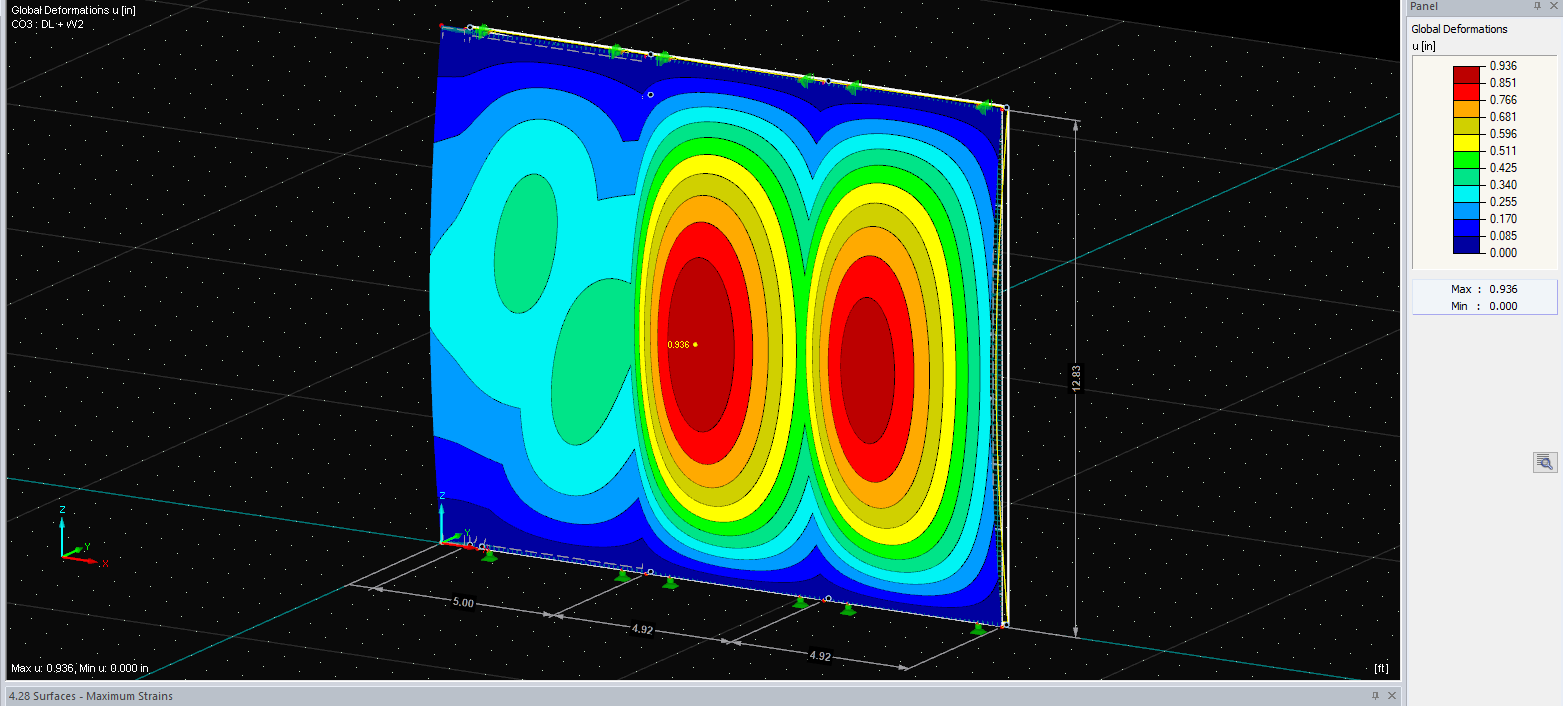

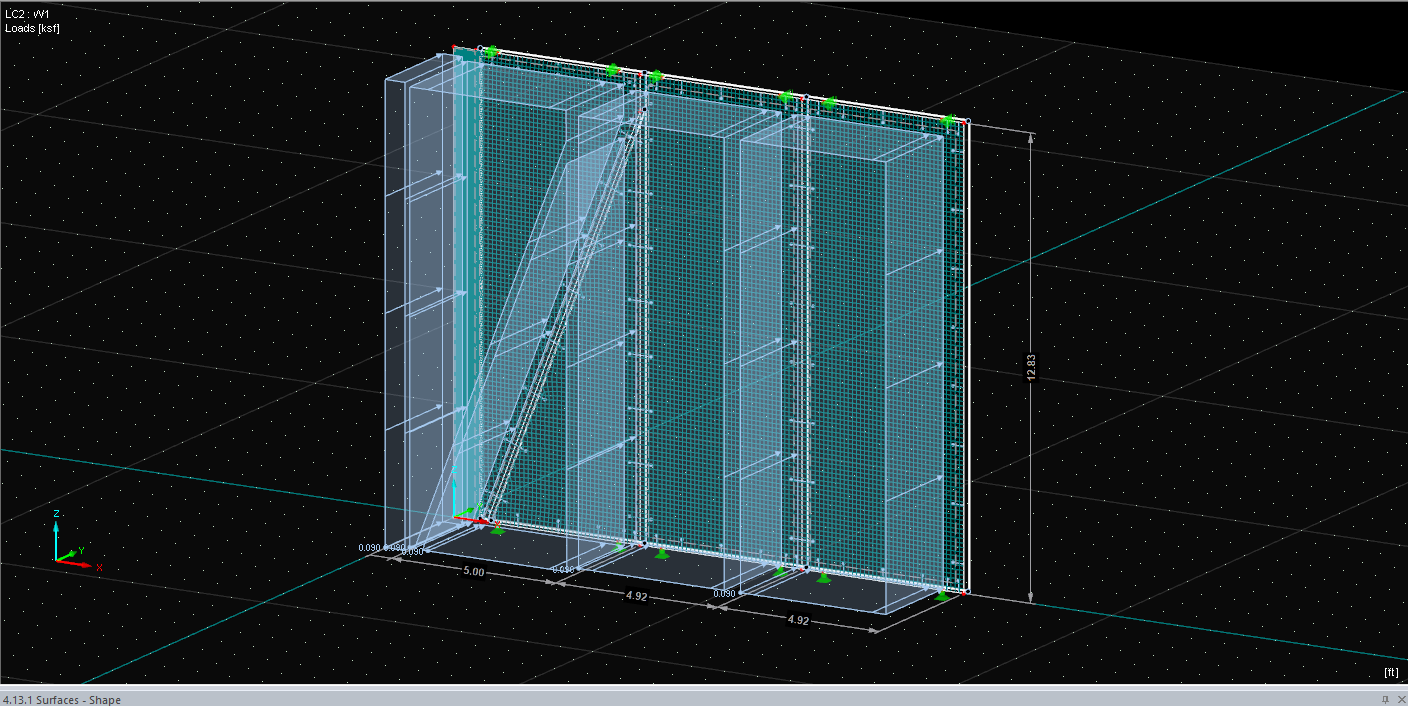

Finite element analysis uses physical simulation to mathematically model the stresses on an engineering design. FEA is an engineering software according to the finite element method (FEM) that allows us to calculate and test complex glazing systems and building materials.What is the Finite Element Method (FEM)

The finite element method involves constructing a digital mesh of the design. This design comprises of innumerable smaller elements. These smaller elements are the “finite elements” of the name. We can then organize data for each of the finite elements. By doing this, we’re able to break down a large-scale equation into multiple, smaller equations for each element. The said equations give an overall projection of the dynamics acting on the engineered module. FEA allows our firm to adjust the prediction accuracy of a concentrated area in a design in order to take corrective measures when problems arise. For instance, in the design of a glass railing system, when adding a concentrated 200 lb. live load we can focus prediction accuracy on the stresses acting on the glass during the load exercise.Why is FEA important?

FEA offers insight into the efficiency of a complex design so that as engineers, we can gain important information on design components and needed adjustments to products and design techniques. Our team is able to completely model an entire glazing system or building component giving the most accurate and realistic results. FEA software allows us to predict how a product reacts to real-world forces such as wind, dead and live loads among others. Finite element analysis provides results that will let us know if a product will fail or pass real-life testing methods as it was designed to. By having the ability to conduct the simulation of a designed model instead of testing a physical product initially, this makes for the perfect tool used in order to consult our clients such as manufacturers for proper testing optimization. Thus, saving our clients time and money. In addition, when using FEA software on projects where we are assigned the design-assist for the facade or other exterior building components, we are able to calculate internal forces as well as support forces, delivering the most accurate type of engineering in lieu of the typical engineering methods.FEA examples: